This is absolutely the very best do-it yourself kit on or off the internet at this time. This cabinet is hand made out of 3/4 inch American made Birch or Oak Plywood. A lot of cabinets these days are made of Chinese plywood. This is a high quality cabinet hand crafted and sanded smooth. It comes with a simple mechanism that has been tested and is guaranteed to be strong, sturdy and superior to all the other mechanisms. I have sold hundreds of these cabinets and mechanisms.

Types:

There are two types of Murphy Bed cabinets on the market today; the Bifold door type and the panel type.The Bifold door type generally sells for less and has a metal frame exclusive of the cabinet that has to be bolted to the floor. The Bifold door over time goes out of alignment and needs to be constantly adjusted, due to the weight the hinges need to carry. I sell these also and they average about $1,000.00 for the cabinet and the metal frame.

Panel Bed:

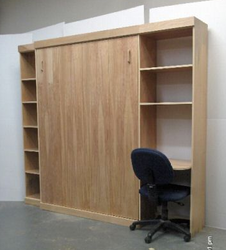

This Panel bed is more of a piece of furniture that can be moved around in the house after it is assembled. It is attached at the top with three 3 inch screws, however it is very important that these screws enter the studs.The front of the panel bed becomes the doors and fold down with the mattress on it. The panel bed has no mechanical springs and no flopping doors,we install two bullet latches in the upper top corners of the panel bed to lock and snap the bed in place when it is closed. We also install a four inch wood handle to the upper right and left corners of the bed face, this is an inconspicuous place yet very functional. We etch the front face so it appears to be four seperate doors. We also add a 3/4 inch x 3 1/4 inch x 59 inch trim board on the bottom and top of the front of the cabinet, this really makes the cabinet look great. I have been building and installing Murphy Beds for over 10 years and as far as I am concerned this is the best system and style on the market today.

Material:

We make it out of 3/4 inch Birch or Oak, both look great. All edges get wood edge banding and every part is sanded with 220 grit sandpaper. The counter balance for the bed is two nitrogen gas pistons. These pistons are not subject to metal fatigue or catastrophic failier. The pistons are held in place by metal plates and pins, this will allow you to change a piston fairly easy if that should become necessary. I have been told by engineers that these pistons should last 20 years with daily use. All the metal parts are painted with two coats of paint. Metal plates are thru bolted to the bed frame and the side panels with furniture grade antique brass finish bolts(flat head). The hinge is a 5/8 inch metal rod on a metal plate that is bolted and screwed to the bed frame and side panel.I have added to these units a 5/8 inch collar that goes between the bed frame and the side panel, this becomes a one time adjustment so the pressure from the piston against the side panel can't draw the side panel into the bed frame. This allows you to maintain a 3/16 inch exposure between the bed doors and the side panel.

Metal Leg:

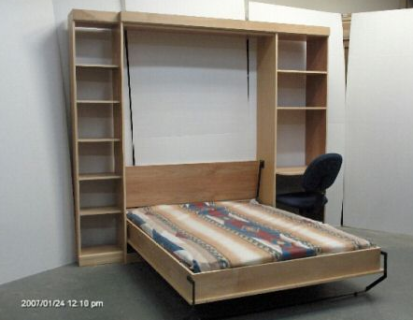

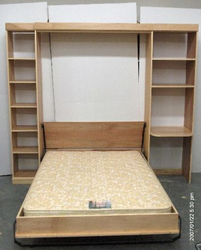

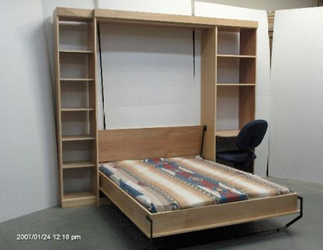

This overall system has been on the market for at least 15 years in many different forms. My system is an overall improvement of these other systems. The most distinguishing characteristic of my beds is the flip over leg. It works as a leg when the bed is down and when bed is up it works to hold the bedding and pillows in place.The other use is to leave the leg out and bring up the bed to have a 59 inch clothes hanger. The leg is in three parts, two legs and one cross bar, they are bolted tightly together so they stay as one unit , The flip over leg is rated to withstand 1000 pounds.Please go to my store to read up on the Full Panel Bed.Ebay Item #260-471-802-848, it is a bit of a long read but it is important. This is a wholesale do-it-yourself kit.This is made out of 3/4 Birch cabinet grade plywood it is shown with three coats of polyurethane

This is a wholesale do-it-yourself kit.This is made out of 3/4 Birch cabinet grade plywood it is shown with three coats of polyurethane on it with no stain.

THIS UNIT IS OFFERED UNFINISHED FOR THIS PRICE.

Stained a color is $175.00 Extra [ pick a color at Home Depot {Minwax] Three coats Water Based Polyurethane is$450.00 extra ,this gives you a completed product.. Allow extra time for finishing.

This is a full or double size bed { you can also get it in queen] with a 15 inch wide by 12 inch deep by 85 inch high cabinet on the left and a 24 inch wide by 22 inch deep desk top on the right, I rounded off the front of the desk and edge banded it. The depth of the desk cabinet is 16 inches. The depth of the bed cabinet is 16 inches.The overall length is 98 inches for a full and the queen is 113 inches. I can make it a little smaller or larger to fit your room.

I drill a 2 inch hole, with a plastic grommet in the desk top in the back for electrical wiring. Home Depot sells a florescent overhead lamp for about $14.00 that works great under the first shelf. I offer lights in the bed compartment for an additional $130.00 this gives you two recessed can lights in black or brass with 40 watt bulbs each.Please allow 3-4 weeks from order to delivery.If you would like Oak add 5%.

Assembly Tools:

Screw Gun

#2 and 3 philips tips

Carpenter Shims

24 inch level

7/16 1/2 inch Wrench

Rubber & Steel Hammer

Flat bar

#2 6 inch square drive

Allen Wrench

4 pc's #8 2 1/2 inch long screws philips [wall studs to cabinet] I don't provide this because of liability

Small set drill bits

Pliars

2 Irwin 8" clamps or helper with a firm grip

Tape measure

Good attitude

Finishing:

I recommend using an oil based stain(natural looks good) remove the stain right away with a dry cloth. This process prevents blotching or color variations in the wood. I apply 3 coats of water based polyurethane, sanding between each coat with 220 sandpaper. Use a short nap 6 incch roller.I like the Pro Series Poly from Home Depot,

I have built hundreds of these, I have it all memorized so you can call and ask a question while you are assembling it. I send pictures, plans and instructions in hard copy plus more photo's by E-mail if you desire them, I am working on a assembly video. It is not easy to assemble but it is not hard either.Thanks for considering my products Dan

Questions call 505-470-8902 cell or 505-286-0856 Call anytime will call right back Thanks Dan

Types:

There are two types of Murphy Bed cabinets on the market today; the Bifold door type and the panel type.The Bifold door type generally sells for less and has a metal frame exclusive of the cabinet that has to be bolted to the floor. The Bifold door over time goes out of alignment and needs to be constantly adjusted, due to the weight the hinges need to carry. I sell these also and they average about $1,000.00 for the cabinet and the metal frame.

Panel Bed:

This Panel bed is more of a piece of furniture that can be moved around in the house after it is assembled. It is attached at the top with three 3 inch screws, however it is very important that these screws enter the studs.The front of the panel bed becomes the doors and fold down with the mattress on it. The panel bed has no mechanical springs and no flopping doors,we install two bullet latches in the upper top corners of the panel bed to lock and snap the bed in place when it is closed. We also install a four inch wood handle to the upper right and left corners of the bed face, this is an inconspicuous place yet very functional. We etch the front face so it appears to be four seperate doors. We also add a 3/4 inch x 3 1/4 inch x 59 inch trim board on the bottom and top of the front of the cabinet, this really makes the cabinet look great. I have been building and installing Murphy Beds for over 10 years and as far as I am concerned this is the best system and style on the market today.

Material:

We make it out of 3/4 inch Birch or Oak, both look great. All edges get wood edge banding and every part is sanded with 220 grit sandpaper. The counter balance for the bed is two nitrogen gas pistons. These pistons are not subject to metal fatigue or catastrophic failier. The pistons are held in place by metal plates and pins, this will allow you to change a piston fairly easy if that should become necessary. I have been told by engineers that these pistons should last 20 years with daily use. All the metal parts are painted with two coats of paint. Metal plates are thru bolted to the bed frame and the side panels with furniture grade antique brass finish bolts(flat head). The hinge is a 5/8 inch metal rod on a metal plate that is bolted and screwed to the bed frame and side panel.I have added to these units a 5/8 inch collar that goes between the bed frame and the side panel, this becomes a one time adjustment so the pressure from the piston against the side panel can't draw the side panel into the bed frame. This allows you to maintain a 3/16 inch exposure between the bed doors and the side panel.

Metal Leg:

This overall system has been on the market for at least 15 years in many different forms. My system is an overall improvement of these other systems. The most distinguishing characteristic of my beds is the flip over leg. It works as a leg when the bed is down and when bed is up it works to hold the bedding and pillows in place.The other use is to leave the leg out and bring up the bed to have a 59 inch clothes hanger. The leg is in three parts, two legs and one cross bar, they are bolted tightly together so they stay as one unit , The flip over leg is rated to withstand 1000 pounds.Please go to my store to read up on the Full Panel Bed.Ebay Item #260-471-802-848, it is a bit of a long read but it is important. This is a wholesale do-it-yourself kit.This is made out of 3/4 Birch cabinet grade plywood it is shown with three coats of polyurethane

This is a wholesale do-it-yourself kit.This is made out of 3/4 Birch cabinet grade plywood it is shown with three coats of polyurethane on it with no stain.

THIS UNIT IS OFFERED UNFINISHED FOR THIS PRICE.

Stained a color is $175.00 Extra [ pick a color at Home Depot {Minwax] Three coats Water Based Polyurethane is$450.00 extra ,this gives you a completed product.. Allow extra time for finishing.

This is a full or double size bed { you can also get it in queen] with a 15 inch wide by 12 inch deep by 85 inch high cabinet on the left and a 24 inch wide by 22 inch deep desk top on the right, I rounded off the front of the desk and edge banded it. The depth of the desk cabinet is 16 inches. The depth of the bed cabinet is 16 inches.The overall length is 98 inches for a full and the queen is 113 inches. I can make it a little smaller or larger to fit your room.

I drill a 2 inch hole, with a plastic grommet in the desk top in the back for electrical wiring. Home Depot sells a florescent overhead lamp for about $14.00 that works great under the first shelf. I offer lights in the bed compartment for an additional $130.00 this gives you two recessed can lights in black or brass with 40 watt bulbs each.Please allow 3-4 weeks from order to delivery.If you would like Oak add 5%.

Assembly Tools:

Screw Gun

#2 and 3 philips tips

Carpenter Shims

24 inch level

7/16 1/2 inch Wrench

Rubber & Steel Hammer

Flat bar

#2 6 inch square drive

Allen Wrench

4 pc's #8 2 1/2 inch long screws philips [wall studs to cabinet] I don't provide this because of liability

Small set drill bits

Pliars

2 Irwin 8" clamps or helper with a firm grip

Tape measure

Good attitude

Finishing:

I recommend using an oil based stain(natural looks good) remove the stain right away with a dry cloth. This process prevents blotching or color variations in the wood. I apply 3 coats of water based polyurethane, sanding between each coat with 220 sandpaper. Use a short nap 6 incch roller.I like the Pro Series Poly from Home Depot,

I have built hundreds of these, I have it all memorized so you can call and ask a question while you are assembling it. I send pictures, plans and instructions in hard copy plus more photo's by E-mail if you desire them, I am working on a assembly video. It is not easy to assemble but it is not hard either.Thanks for considering my products Dan

Questions call 505-470-8902 cell or 505-286-0856 Call anytime will call right back Thanks Dan